We use cookies

This site uses cookies to provide you with a great user experience. You can view our cookies policy here.

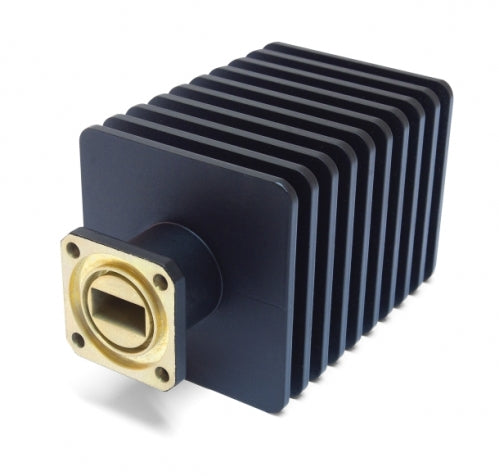

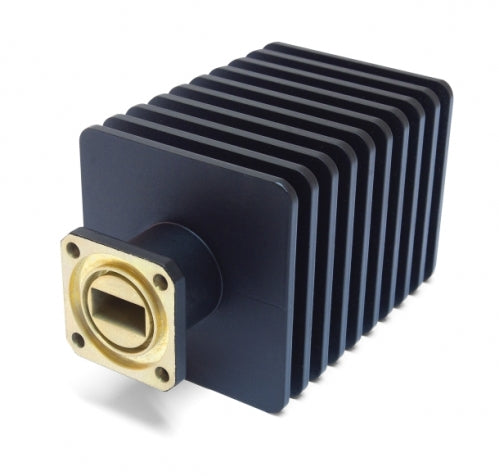

We offer a range of Low Power and Sliding load terminations has been designed to offer optimum Return Loss Performance.

We offer a range of Low Power and Sliding load terminations has been designed to offer optimum Return Loss Performance.

The standard sliding loads are assembled in the same way as the standard fixed loads using selected waveguide tube and precise positioning of the flange interface. Operation of the sliding element is by a push/pull mechanism and a locking screw is provided for repetitive measurements.

Specification:

V.S.W.R: See table (based on spot frequency operation)

Material: Brass

Load material: Iron loaded resin

Finish: Blue paint

Download the Loads (1.5kW to 3kW, Convection and Watercooled) specifications.

Add your details below to find out more about this product. We'll aim to get back to within 48 working hours.

Choose options

Join Us

Our expert team is available to help you dimension the optimal solutions for your VSAT Terminal and Gateway needs.